Car Wash systems

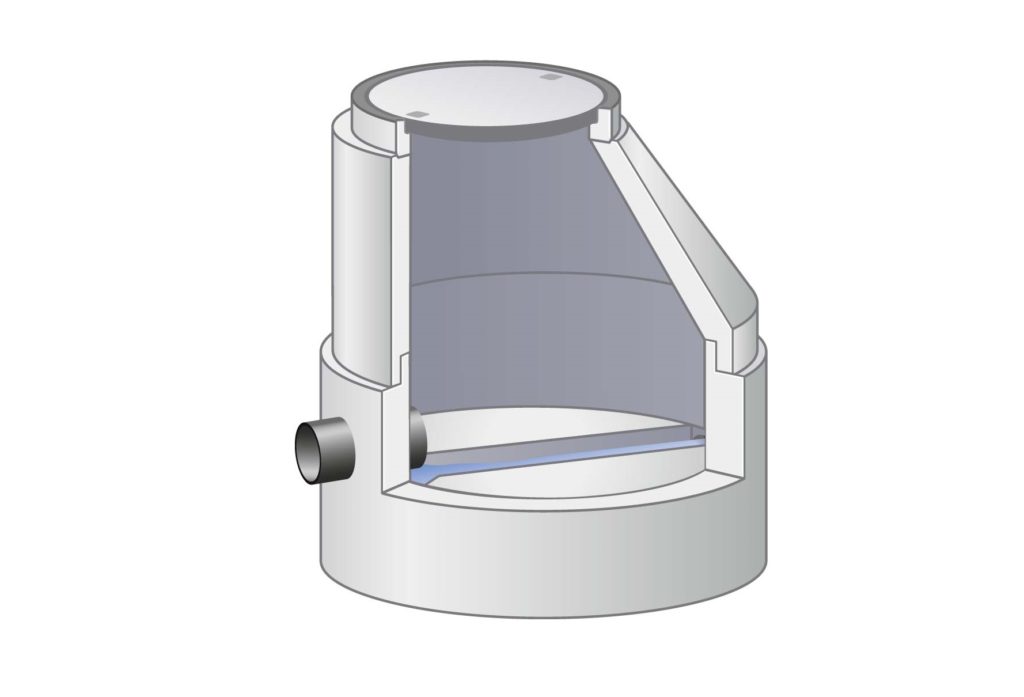

Mall – NeutraSed Sludge Trap

NeutraSed sludge trap for petrol separators and coalescence separators Benefits : Sludge trap: 650 – 18,300 litres According to EN 858, DIN 1999-100 and 1999-101 50% of the volume is used to store sludge The volume flow is introduced into the container in a flow optimised manner Adapted to the respective requirements of different manufacturers…

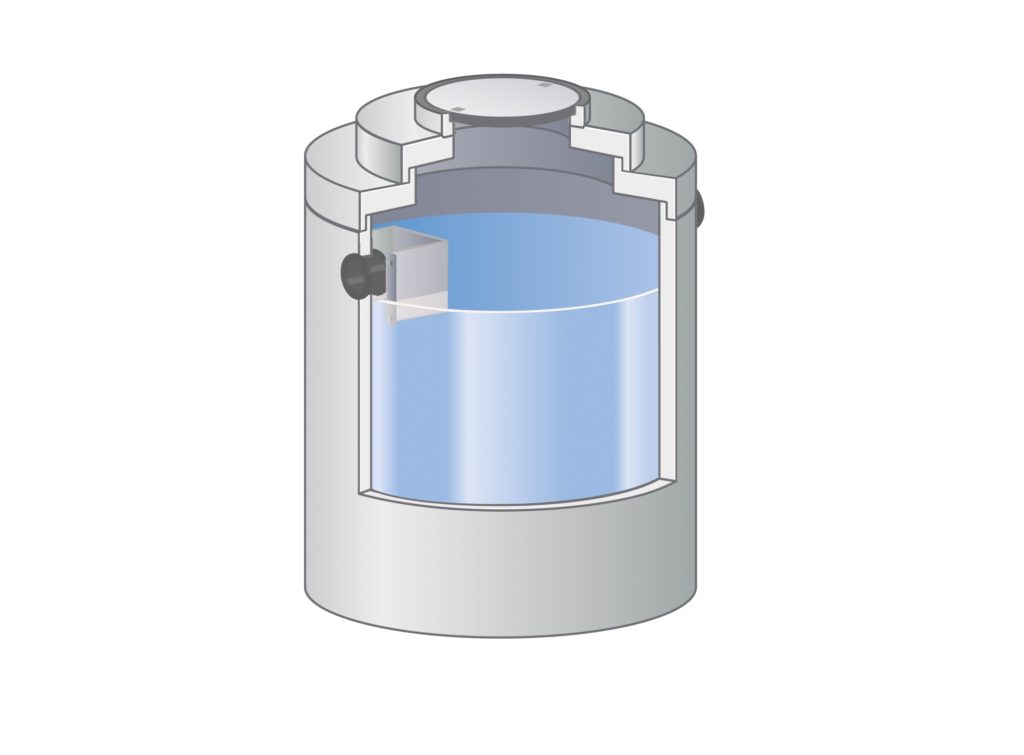

Read MoreMall – NeutraPlus II Petrol Separator

NeutraPlus petrol separator (class II) Benefits : Automatic locking guided in a protective tube that protects the floating ball from damage All components made of high quality stainless steel Separated light liquids can be disposed of independently of sludge storage According to EN 858 / DIN 1999-100 / -101 with automatic locking The light water-repellent…

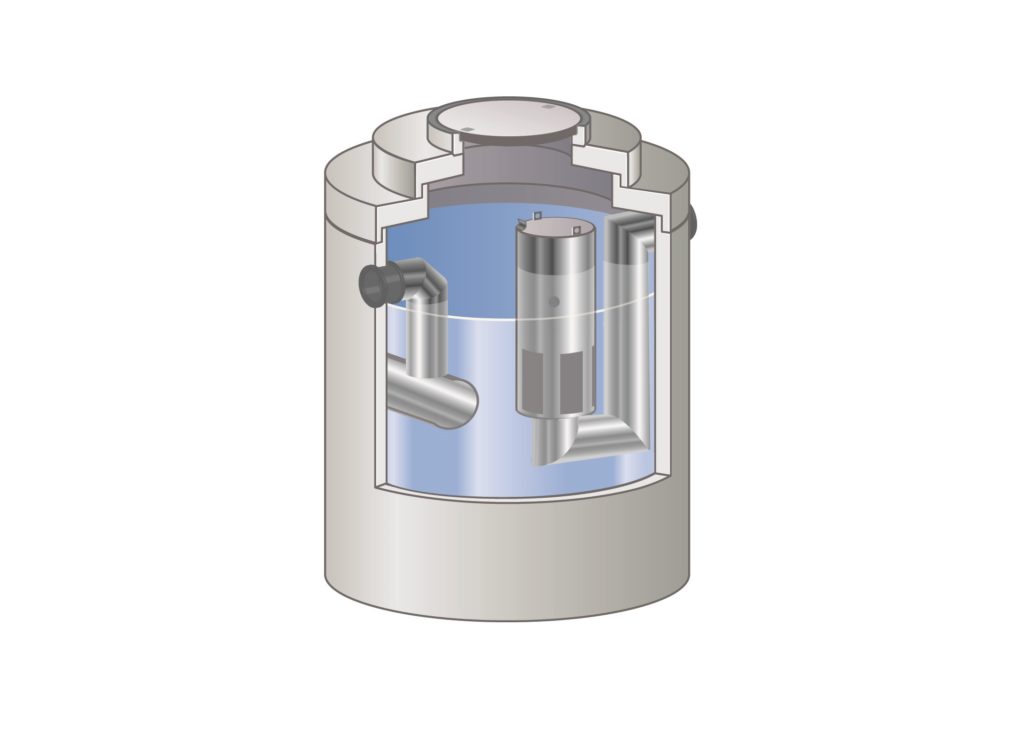

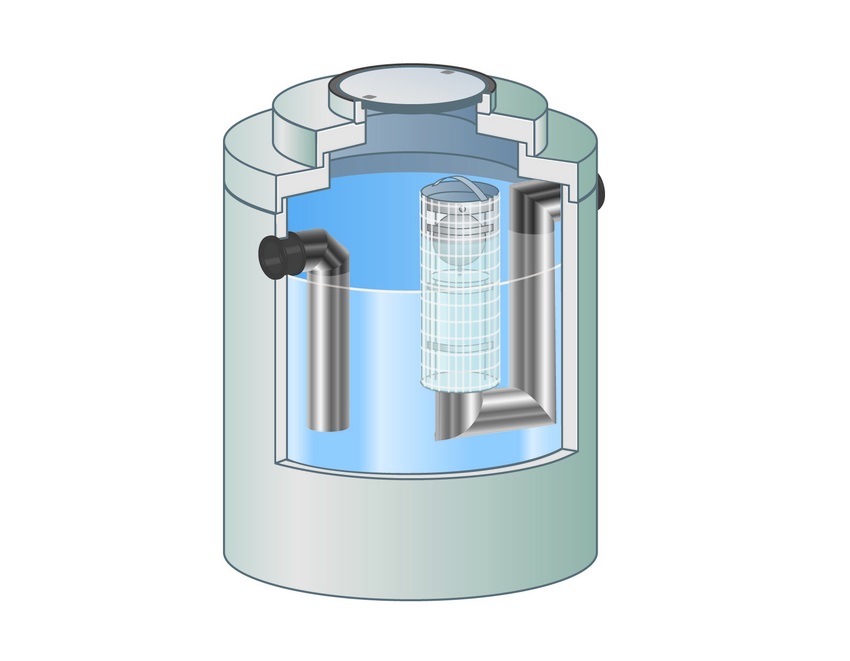

Read MoreMall – NeutraStar I Coalescence separator

Coalescence Separator (Class I) NeutraStar also holds the certificate issued by the Austrian Standards Institute in accordance with ÖNORM B 5101. Benefits : Highly efficient coalescence level Good accessibility of the coalescence facility Automatic locking device Suitable for biodiesel Open-cell PU insert According to DIN EN 858, DIN 1999-100 and DIN 1999-101 According to EN…

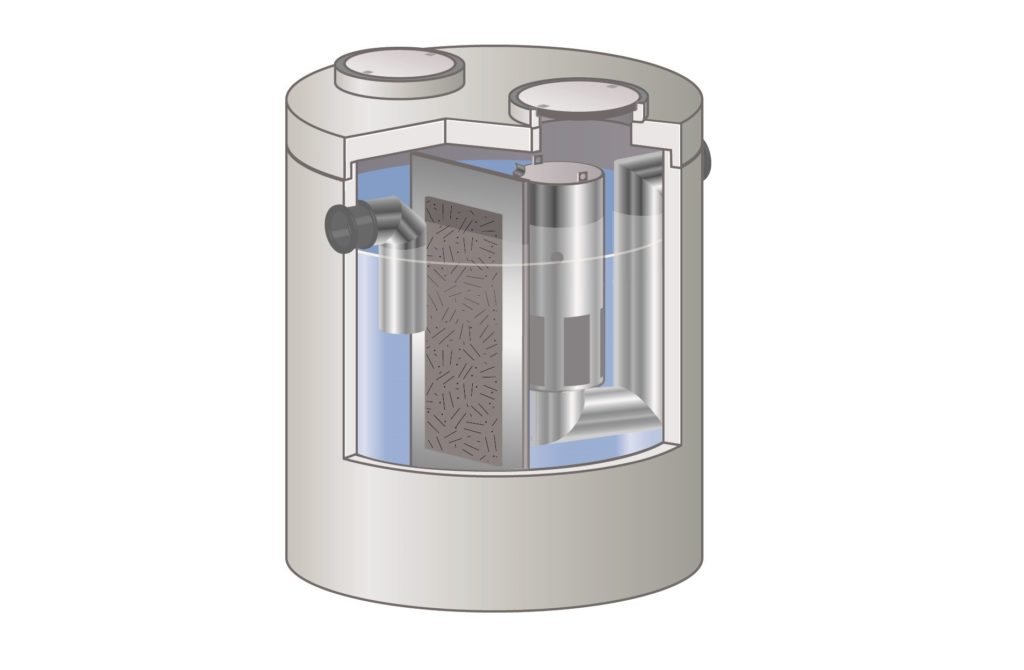

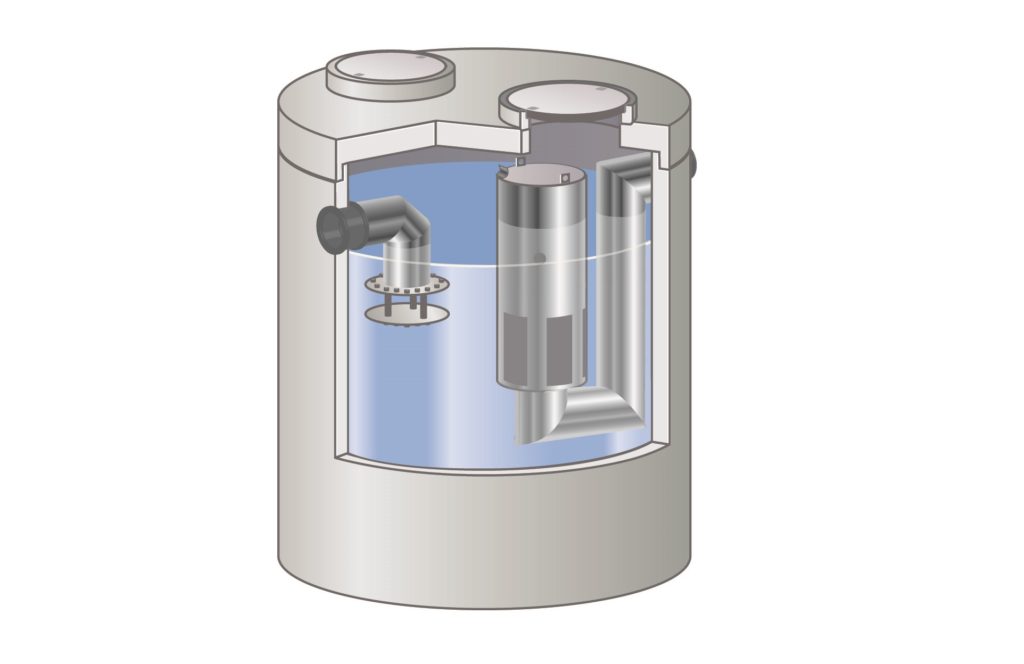

Read MoreMall – Neutracom I

Coalescence separator (Class I) and NeutraCom sludge trap Benefits : Just one building, one relocation process… One entry and one exit Compact design with a small footprint Corrosion-resistant built-in parts designed for continuous use Functional elements can be viewed, removed and reinserted from above, even when the system is full, without the contents having to…

Read MoreMall – NeutraSpin I

NeutraSpin – the separator for difficult operating conditions Benefits : Maintenance-free self-cleaning coalescence device Free ball passage (at least 150 mm) with wear-free hydrodynamic coalescing device at the inlet Automatic closure at the drain Large oil storage volume Optimal separation of sedimentary materials Sludge trap standard size according to EN 858 Articulated hose couplings, suitable…

Read MoreMall – NeutraCheck

NeutraCheck sample shaft at upstream separator Benefits : According to EN 858 and DIN 1999-100 Inspection, maintenance and cleaning of the system in operation Ventilated manhole cover Articulated hose couplings No permanent build-up in the pipes possible Can be used after each separation system Sampling Wells The sampling well is used to take representative wastewater…

Read MoreWash materials

POLYETHYLENE brush We recommend this proven wash material for wash unit concepts where simple and cost-effective wash technology is of main importance • Normal longevity • Highest cleaning performance • Average material abrasion on the vehicle’s paint finish • Vehicle has a sufficient gloss finish • Available in a wide array of colours • Universal…

Read MoreMaxi flex +

Inclined side cylinders for an optimised rear wash Roll-Over Systems with MAXI FLEX+ set new standards for rear wash cycles. The MAXI FLEX+ system allows the two side cylinders to be inclined by up to 25°, the largest inclination available on the market. The only way to ensure that the rear of the vehicle, rear…

Read MoreWheel master

WHEEL MASTER – The intelligent wheel washing system ACCOMMODATING EVEN THE BIGGEST WHEELS ON THE MARKET Our answer to the increasingly diverse range of wheel and rim sizes goes by the name of WHEEL MASTER: The intelligent wheel washing system detects the wheel position and diameter by way of a sensor system and selects the…

Read MoreVisus

Colour display system VISUS The VISUS colour display system gives the car wash unit a modern, contemporary look. This central communication unit for wash customers can be seen visibly from a distance. Only the respective, current, important information is displayed and, unlike other systems, no information overlapping takes place. Thus, the VISUS colour display system…

Read More