Omer – Bipark 26

Bipark

Bipark 26 is included in the Double stackers’ range and is the simplest product and very user friendly.

It doesn’t need a pit. The first vehicle is parked on the platform and then lifted up till a height of 1,80 mt. allowing another vehicle to be parked underneath. In this way we can double the parking space.

Description:

-

The platform of Bipark 26 is a compact double car stacker that lifts the car smoothly and quickly into position.

The platform has a lift capacity of 2,600 Kg and will accommodate the new generation SUVs, 4-wheel-drive vehicles and low clearance sports cars.

Moreover, the galvanized platform structure is designed to prevent fluids from the upper vehicle dripping down on the lower one.

The overall compactness

of the product reduces the space requirements to the barest minimum, and thus allowing several vehicles to be parked in a relatively small space. The pushbutton control panel can be installed in the most convenient position for controlling the lift depending on customer’s requirements.

The platform has a front wheel stop bar set at the front edge of the platform.

-

When this platform

is raised to maximum height, any type of standard passenger vehicle can be parked underneath, while still ensuring easy loading and removal of vehicles.

This view

shows how compact the platform is and how little space is required by the unit’s electro-hydraulic system, the true heart of this machine.

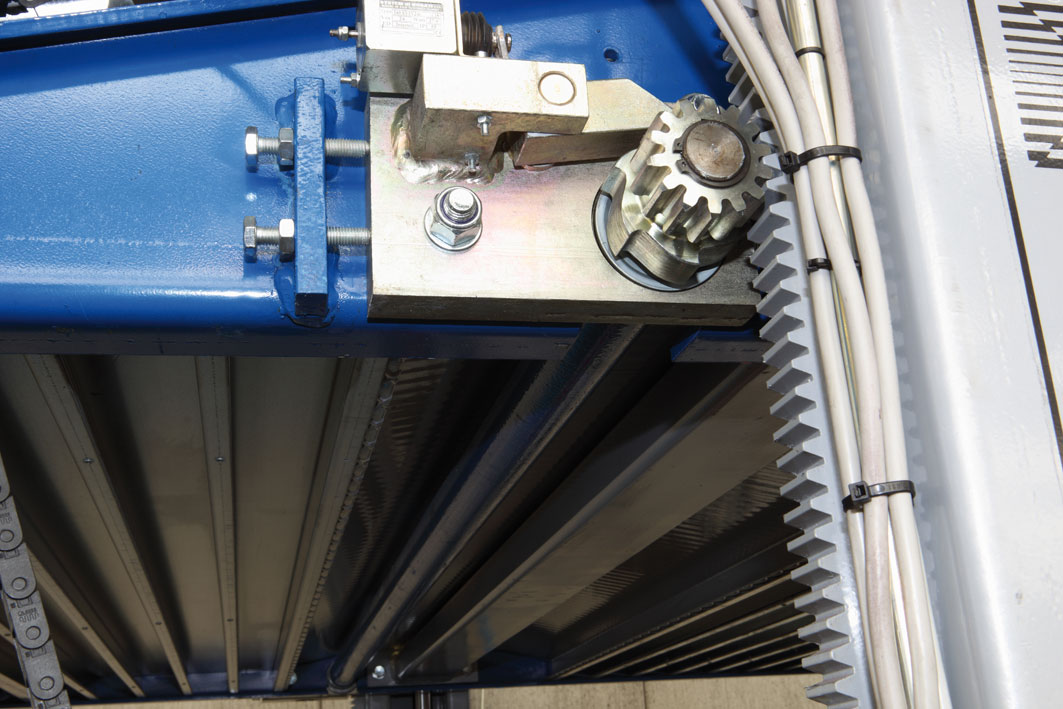

The unique torsion bar

locking mechanism – a toothed pinion that is integral to the torsion bar itself and the electro-magnetically operated dog – ensure that the platform can be safely stopped at any height, even after departing the highest position.

The view

seen from above, shows the platform carriage.

This carriage is guided by wheels and molybdenum disulphide reinforced nylon guides. This combination reduces friction between column and carriage and thus lowers the power needed for operation. Moreover, it ensures that the machine remains in good working order, guaranteeing a long lifespan and reducing the need for maintenance. In addition, the unique shape of the column significantly reduces unit dimensions while increasing resistance and stiffness.

The torsion bar-pinion assembly

that engages the rack aligns the platform so that the weight on the platform does not need to be balanced. This allows the car can be parked facing forewords or backwards or to be offset side to side.

The push button

control panel has a mushroom-shaped emergency button and a lockable activation key.

If several of these units are used side-by-side, the keys can all be the same, or each one can be different, again depending on customer need.

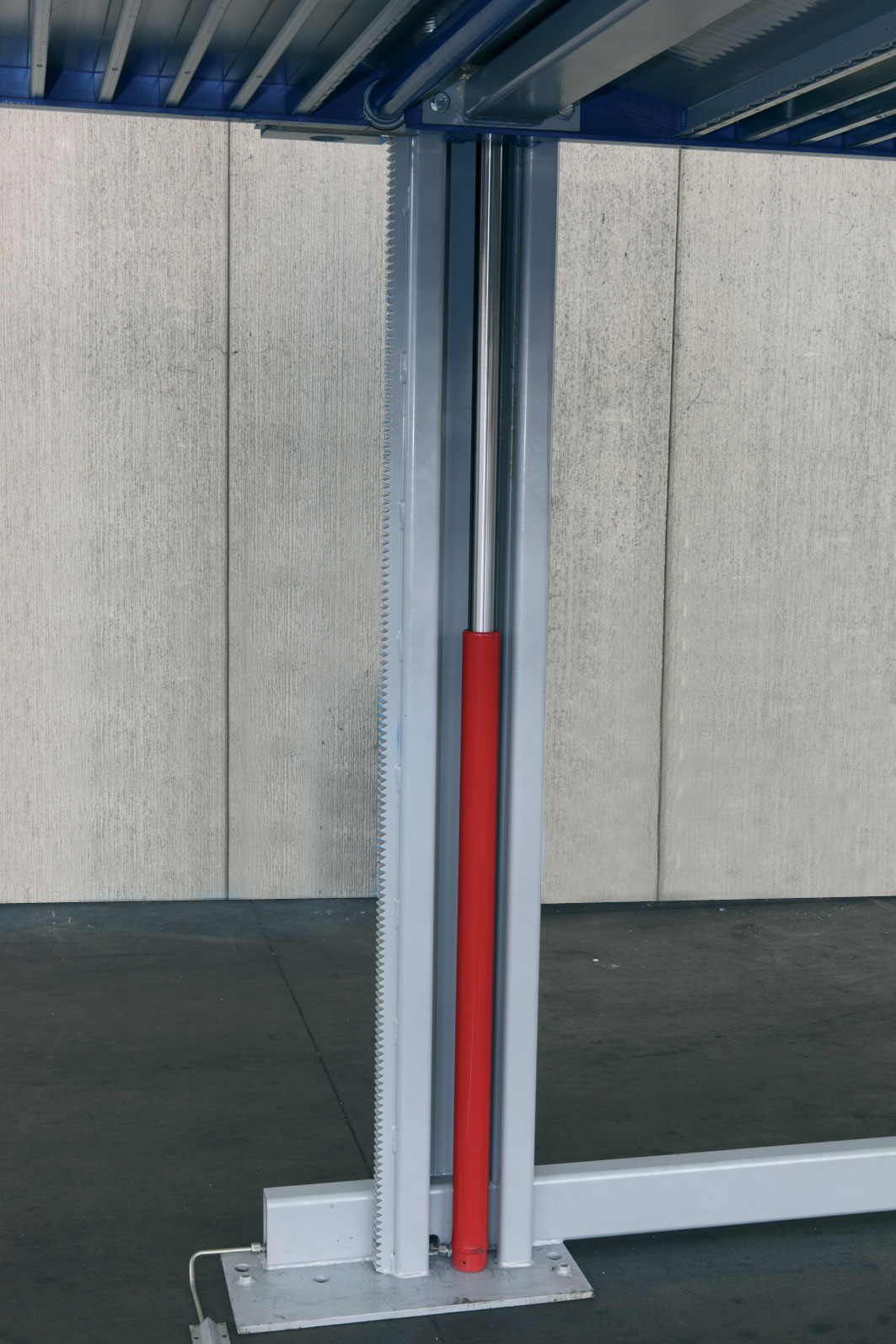

The hydraulic double

extension lifting cylinders (RAM – manufactured by O.ME.R. S.p.A.) permits direct lifting, without any auxiliary aids such as cables or chains.

The compactness

of the electro-hydraulic assembly and the electrical panel – located at the top of the left hand column – ensures the utmost efficiency in minimal space, thus ensuring unhindered parking of the car.

The vertical lifting

height of the platform is set during the initial installation by means of locking steel plates mounted at the top of the columns, thus guaranteeing safety and determining the peak lifting height, designed to customer requirements and enviroment.

Manufacturer’s website : Omer-Park

Product website : Omer-Park-Bipark