Kaeser – Integrated compressed air dryer DSG

Various drying technologies

Integrated refrigeration dryer

Even for oil-free compression rotary screw compressors, refrigeration dryers are the go-to choice for delivering best possible energy efficiency and favourable investment cost when requiring pressure dew points to +3 °C. Pressure dew points below +3 °C are provided by desiccant dryers.

Integrated i.HOC rotation dryer

The optional i.HOC rotation dryer for integration in the rotary screw compressor can reliably and efficiently achieve pressure dew points as low as -30 °C. The hot compressed air from the second compression stage is used to regenerate the desiccant.

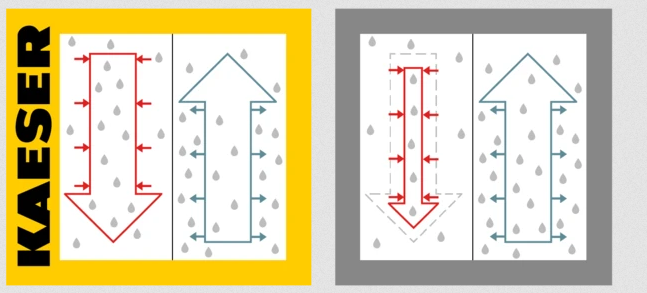

i.HOC superior full-flow regeneration

The i.HOC (Integrated Heat of Compression Dryer) system uses 100 % of the heat of compression from the second compression stage for drying purposes (full-flow regeneration). This heat, which is produced in any case, is therefore effectively available at zero cost.

No additional energy input for the drying process

Higher regeneration potential than with partial-flow regeneration dryers

Full performance, even with low compressor load

The advantages of full-flow regeneration become obvious, especially with increased coolant temperatures. Kaeser rotary dryers achieve outstanding drying results even without additional electric heating of the regeneration air.

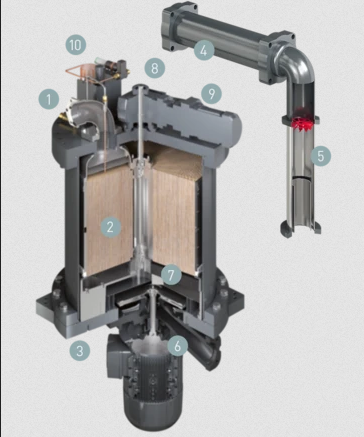

View inside the integrated rotary dryer

- Regeneration air inlet

- Regeneration air outlet

- Condensate separation

- Radial fan inlet

- i.HOC outlet

i.HOC in detail

- Regeneration air inlet

- Drum (silica gel desiccant)

- Regeneration air outlet

- Heat exchanger stage 2

- External condensate separator

- Radial fan

- Demister (droplet separator)

- Rotation dryer outlet

- Drum motor

- Pressure dew point sensor (optional)

Manufacturer's website : Kaeser

Product website : Kaeser-Compressed-air-dryer

Product PDF : P-651-31-FR-16_23-5600