Corghi – Monster AG-TT

A “performance monster” for professionals operating in the industrial tyre sector

Corghi, a leading tyre changer manufacturer with an in-depth knowledge of the problems faced by the industry, has opened up a new frontier for professionals operating in the heavy tyres sector.In response to the pressing demands of tyre repairers specializing in trucks, earth moving machinery, and agricultural machinery, as well as those operating in transport fleet service shops, Corghi’s researchers have developed and patented a new and revolutionary heavy duty tyre changer.

In addition to featuring the most advanced technologies, the Monster AG TT also embodies all the characteristics necessary to render it an essential and irreplaceable tool in terms of quality and operator safety in the industrial tyre sector

Major advantages in 5 strengths

Significant reduction in fatigue

Exceptional protection for rims and tyres

High performance

Maximum safety

Completely universal

As of today, with the Monster AG TT, the specialized tyre repair profession has changed considerably, offering greater efficiency, speed and service quality to operators and customers alike

Significant reduction in fatigue

The Monster AG TT is a super-automatic and revolutionary tyre changer. It’s the world’s only tyre changer to be equipped with a “Leva la Leva” (without lever) in order to significantly reduce the fatigue and risks posed to professionals specializing in the demounting of all types of wheels: trucks, buses, agricultural vehicles, and earth moving machinery. Equipped with an automatic wheel clamping device andturntable (without the use of extensions), the Monster AG TT features an electronic system for memorizing the rim diameter and wheel position, as well as a “Side to Side” device, which allows the tools to be automatically transferred from one side of the tyre to the other.

Exceptional protection for rims and tyres

The entire tool holder block is hydraulically operated. It includes the “Leva la Leva” (without lever) for demounting the tyre in an entirely automated manner, as well as a special bead breaker disc, which ensures the perfect tilt throughout every stage of the operations, based on the hydraulic movement. One of the system’s essential features is the arm that controls the tool holder block, which always maintains a perfect tangencybetween the wheel and the tools by coordinating its movements with the turntable. This helps to reduce tension and avoid unnecessary contacts, thus ensuring maximum protection for the integrity of the rims and tyres.

High performance

The Monster AG TT has been designed and built to ensure maximum flexibility and functionality for the operator. Thetool block’s single position on the trolley renders the work operations quicker and easier; the new play recovery slides allow for any play caused by wear to be eliminated; the function for memorizing the position of the tools expedites positioning during mounting and demounting operations, while the synchronized handling of the spindle and the tool trolley, the electro-hydraulic power unit with a user adjustable display, and the possibility of automatically positioning both the hook and the disc in tangency with the rim, render the Monster AG TT an irreplaceable and one-of-a-kind unit.

Maximum safety

In addition to reducing fatigue, the Monster AG TT has also been designed to ensure maximum protection and safety for the operator. The tyre changer’s design excludes the need for a base, thus resulting in the elimination of any height offsets, which can certainly be hazardous when loading largeand heavy wheels. This design feature allows the operator to work under conditions of complete safety, with the wheel raised off the ground by just a few centimetres. What’s more, the new manipulator with ergonomic controls allows for all the operations to be controlled without ever coming into contact with the tool block.

Completely universal

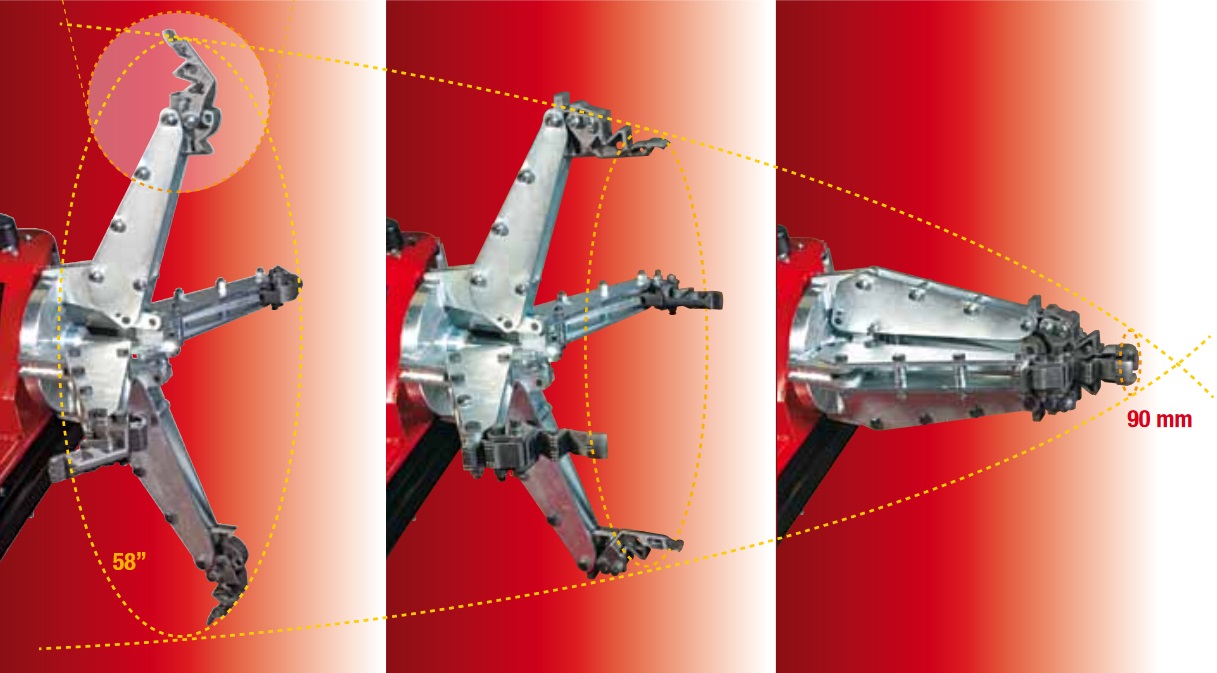

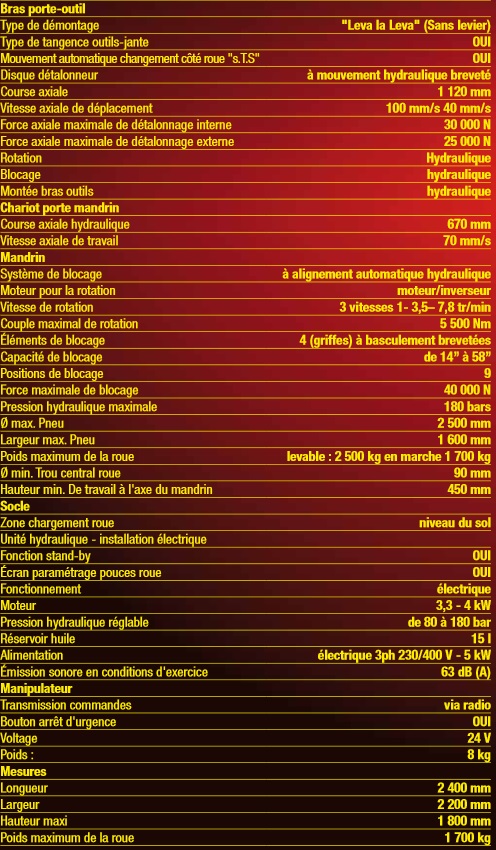

The Monster AG TT unit’s universal nature is ensured by the new turntable clamping system, which consists of tilting claws with 9 direct clamping positions, from 14” to 48”, and up to 58” with tilting. The system is predisposed to clamp rims with a minimum hole size of 90 mm. The turntable is equipped with a moto inverter, which allows for the optimal speed to be automatically obtained for each individual operation, including tyre grooving operations.

Corghi research and experience, for an unsurpassable product

The new and exclusive tilting claw ensures complete adaptability to every type of rim.

From 90 mm to 58”, the Monster AG TT can be used for the tyres of any type of motorized vehicle

The S.T.S. (Side To Side) device allows for the tool block to be automatically transferred from one side of the tyre to the other

The new manipulator with ergonomic controls ensures the tyre changer’s complete functionality, with no need for the operator to come into contact with the tools

Tool’s sequence of automatic movements :

1bead connection

2position for rim tangency

3“Leva la Leva” (without lever) demounting positio

Bead breaker disc sequence of automatic movements

1disc in tangency with the rim (minimum tilt)

2disc tiltable to maximum tilt

3tool unit rotatio

The ergonomic control unit with wheels (trolley-style) is separate from the machine, and is designed to facilitate the operator’s work.

The electro-hydraulic power unit with display can be positioned as desired and allows the user to save all the data relating to the tyre being processed

Manufacturer’s website : Corghi

Product website : Corghi-Monster-AGTT

Prouct PDF : Corghi – Monster-AGTT